Choosing the Right Heavy-Duty Baler: Two Ram Baler vs. Single Ram Baler

March 7, 2023

Baler machines are imperative to reducing waste volume for businesses and manufacturing facilities that generate abundant amounts of trash, recycling, or cardboard materials. Most balers operate by utilizing a hydraulic cylinder that compresses the waste into easy-to-manage bundles that reduce storage capacity needs. Like most products, balers are available in several design formats, catering to the needs of various-sized businesses and waste production volumes.

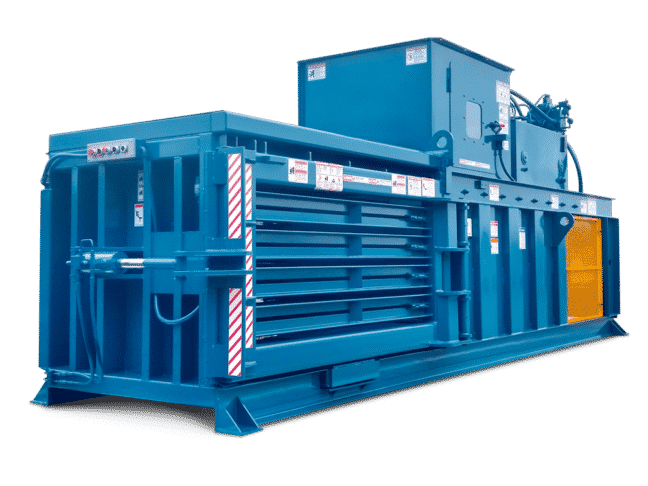

Heavy-Duty Balers

Heavy-duty balers utilize high-performance hydraulic pistons to crush garbage, recycling, and other waste materials into simple transportable cubes that take up less space than conventional dumpsters and recycling units. Large, heavy-duty balers are manufactured from tough and durable materials that can withstand years or decades of use when properly maintained and serviced regularly. Compared to low- and medium-duty balers, heavy-duty balers and compactors can withstand more wear and tear due to higher-quality parts.

What Materials can be Placed in a Baler?

Balers can accept a host of materials. The type of materials used within a baler will depend on the industry in which it’s used. Baler applications include, but are not limited to:

- Garbage

- Cardboard

- Steel

- Foam

- Textile

- Agriculture

What is a Single Ram Baler?

Single ram balers are the most common baler used for material recycling, producing compression using a single hydraulic cylinder. Single ram balers are manufactured horizontally or vertically, depending on the orientation of the ram. Horizontal, single ram balers can be divided into closed-end and open-end extrusion balers.

What is a Double Ram Baler?

Double ram balers utilize dual hydraulic cylinders, also referred to as two ram balers and twin ram balers. The first cylinder acts as the compression mechanism, with the second acting as a control mechanism. Double ram balers can run vertically or horizontally and are ideal for compacting large, high-density materials such as rubberized products that can rebound during the compression phase.

What are Open-End Extrusion Balers?

Available with one or two rams, open-end extrusion balers compress materials through a long extrusion chamber. The ram compresses the bale against the side of the last bale formed in the extrusion chamber, eliminating the need for other parts, such as ejection rams and separation doors. Open-end extrusion balers are quicker than closed-end balers and feature an automatic tying mechanism that expedites the bale removal process.

What are Closed-End Balers?

Closed-end balers utilize a single ram design that automatically ejects and releases the bale. Closed-end balers are generally manufactured with a horizontal design, allowing for heavier bales to be formed regardless of the material. Horizontal closed-end balers are the standard for the industrial baler industry. They enable businesses to make larger and heavier bales irrespective of the types of materials being baled. Closed-end balers may repeat compaction multiple times until the chamber is full and the ram can no longer move.

Which Baler Type is Best for Your Needs?

The choice between a single ram baler and a two ram baler will come down to your specific needs. A single ram open-end extrusion may be your best option if you’re in the market for a smaller baler that can provide automatic tying capabilities. Suppose you’re looking for a larger baler that uses a dual ram design with horizontal or vertical functionality options. In that case, a dual ram baler may provide the best opportunities for your business. Twin ram balers also allow changing materials easily and quickly, with a larger range of cylinder sizes.

Additional Heavy-Duty Baler Considerations

Additional considerations when choosing a single ram or two ram baler include:

- Operator’s platform

- Bale door style

- Fully lined chambers

- Dual- or quad-motor systems

- Removable end wall

The size of the baler in relation to the available space and footprint of the facility should also be considered before making a purchase. Site prep for mounting options, floor supports (beams, plates), and electrical service must be ready before the baler arrives. Left- or right-hand ejection, feed direction, and space for removing the bale should also be considered.

EMP is Your Trusted Resource for Single- & Dual-Ram Balers

In the market for a premium, heavy-duty, single- or twin-ram baler? EMP has you covered. We partner with the world’s most advanced baler manufacturers to provide heavy-duty baler options that meet your needs. These include open-end and closed-end vertical and horizontal balers that provide extraordinary benefits.

Whether your project requires a single ram or dual ram baler, EMP provides the resources you need to make an informed decision. Contact us with any questions, and we’ll be happy to assist.