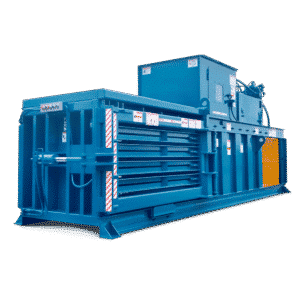

Excel Manufacturing 2R Series Two Ram Balers

There is a reason Excel’s two ram balers are known for their outstanding functionality and quality. The proprietary combination of interlocking construction and integrated control systems produces an indestructible, automated two ram baler. Thereby eliminating the need for a full-time operator.

Features

- The 2R9 & 2R10 balers are manufactured standard with either left-hand or right-hand eject.

- Operator-Free Operation

- 50HP TEFC Motor, Standard Voltage – 460 Volt, 60 Hertz, 3 Phase (2 – 50 HP, 2R10)

- Excel Autonetics™ – Absolute Ram Position Sensor with Electronic Display

- U.S. Wire Tie Systems Automatic 342 Tier with Turbo Motor

- Industrial Hardened Logic Controller

- Fully Lined with Hardox® 400 Replaceable Wear Liners

- 300 Gallon Hydraulic Reservoir with Regenerative Circuit (600 gallon 2R10)

- Excel’s 1-2-3 Warranty (1 year Labor, 2 Years Parts, 3 years Structural & Cylinder) (USA Only)

- Upper and Lower Photo Eyes (sender/receiver upper photo eye with integrated conveyer control)

- NEMA 12 rated Enclosures and Controls with Conveyer Starter

- Installed and Working Modem for On-Line Diagnostics

- Castle Key Safety Interlocking Entry System

- Bale Chamber Penetration (2R9 baler is 27″) (2R10 baler is 24″)

- Automatic Bale Release Door

- Bale Discharge Platform

- One Spool of 12 Gauge Ultra High Tensile Galvanized Wire

- Paint – Excel Blue

- Air to Oil Heat Exchanger

- Integrated Steel Platen Wiper

- UL, CUL, CE Approved

- Bale Counter

- Hardened, Serrated, Turntable Cutting Knives

- Hour Meter

- 9″ eject cylinder

- Separation Door for Solid Waste and Scrap Applications (Available Option)

- Available with Excel integrated conveyers with rubber or steel belts for a turn-key system

Specifications

Structural

- AUTOMATIC CLOSED END BALING PRESS

- HEIGHT : 62” Loading 52 1/2” Frame (158cm)

- LENGTH : 179” (455cm)

- WIDTH : 77” (196cm)

- CHAMBER : 47”L (119cm) x 60”W (152cm) x 30”H (76cm)

- FEED OPENING : 54”W (137cm) x 35”L (89cm)

- BALER SHIPPING WEIGHT : 18,760 lbs. (8,509kg) (as shown)

Performance Data

- AUTOMATIC CLOSED END BALING PRESS

- PUMP : 34 gal. (130 liters) Pressure Compensated HorsePower Limited Piston Pump, 4,000 PSI Rated

- DIRECTIONAL VALVE : D08 Pattern, Hi-Flow Cushion Shift Design

- CYLINDERS : (2) 6” (15cm) Bore x 74” (188cm) Strokex 4” (10cm) Hard Chrome Rod

- OIL RESERVOIR : 105 gal. (399 liters)

- DOOR LATCH CYL. : N/A

- MOTOR : TEFC 208, 230, 460 Volt, 60 Hertz, 3 Phase

- ENCLOSUR : NEMA 12 Rated, UL Approved

- CONTROLS : UL/CUL/CE Approved, NEMA 12 Rated

- HYD SYSTEM PRESSURE : 4,000 PSI (276 Bar)

- OVERALL PLATEN FORCE : 159,400 lbs. (72 tonne)

- PLATEN PSI : 92 PSI (6.33 BAR)

- CYCLE TIME : 46 sec. – 30 sec. Short Stroke

- TARGET BALE SIZE : 60”L (152cm) x 48”W (122cm) x 30”H (76cm)

Bale Weights *

- OCC : 1,200 lbs. (544kg) TPH 2.4

- MAGAZINES : 2,000 lbs. (907kg) TPH 5

- NEWSPAPER : 1,500 lbs. (680kg) TPH 4.5

- OFFICE PAPER : 1,600 lbs. (726kg) TPH 4.8

- HDPE : 1,100 lbs. (499kg) TPH 1.7

- PET : 800 lbs. (363kg) TPH 1.1 (May vary with percent of capped bottles)

- ALUMINUM CANS : 625 lbs. (284kg) TPH 1.9

- TIN CANS : 1,200 lbs. (544kg) TPH 3

Applications

2R9 Two Ram Balers bale the following materials:

- Office Paper

- Newspaper

- OCC

- Magazines

- PET

- HDPE

- Aluminum Cans

- Tin Cans

- Plastic Film

- Carpet Padding

- Textiles

- Other materials

Features

- The 2R9 & 2R10 balers are manufactured standard with either left-hand or right-hand eject.

- Operator-Free Operation

- 50HP TEFC Motor, Standard Voltage – 460 Volt, 60 Hertz, 3 Phase (2 – 50 HP, 2R10)

- Excel Autonetics™ – Absolute Ram Position Sensor with Electronic Display

- U.S. Wire Tie Systems Automatic 342 Tier with Turbo Motor

- Industrial Hardened Logic Controller

- Fully Lined with Hardox® 400 Replaceable Wear Liners

- 300 Gallon Hydraulic Reservoir with Regenerative Circuit (600 gallon 2R10)

- Excel’s 1-2-3 Warranty (1 year Labor, 2 Years Parts, 3 years Structural & Cylinder) (USA Only)

- Upper and Lower Photo Eyes (sender/receiver upper photo eye with integrated conveyer control)

- NEMA 12 rated Enclosures and Controls with Conveyer Starter

- Installed and Working Modem for On-Line Diagnostics

- Castle Key Safety Interlocking Entry System

- Bale Chamber Penetration (2R9 baler is 27″) (2R10 baler is 24″)

- Automatic Bale Release Door

- Bale Discharge Platform

- One Spool of 12 Gauge Ultra High Tensile Galvanized Wire

- Paint – Excel Blue

- Air to Oil Heat Exchanger

- Integrated Steel Platen Wiper

- UL, CUL, CE Approved

- Bale Counter

- Hardened, Serrated, Turntable Cutting Knives

- Hour Meter

- 9″ eject cylinder

- Separation Door for Solid Waste and Scrap Applications (Available Option)

- Available with Excel integrated conveyers with rubber or steel belts for a turn-key system

Specifications

Structural

- HEIGHT : 62” Loading 52 1/2” Frame (158cm)

- LENGTH : 179” (455cm)

- WIDTH : 77” (196cm)

- CHAMBER : 47”L (119cm) x 60”W (152cm) x 30”H (76cm)

- FEED OPENING : 54”W (137cm) x 35”L (89cm)

- BALER SHIPPING WEIGHT : 18,960 lbs. (8,600kg) (as shown)

Performance Data

- PUMP : 34 gal. (130 liters) Pressure Compensated HorsePower Limited Piston Pump, 4,000 PSI Rated

- DIRECTIONAL VALVE : D08 Pattern, Hi-Flow Cushion Shift Design

- CYLINDERS : (2) 6” (15cm) Bore x 74” (188cm) Strokex 4” (10cm) Hard Chrome Rod

- OIL RESERVOIR : 105 gal. (399 liters)

- DOOR LATCH CYL. : 4” (10cm) Bore x 6” (15cm) Strokex 2” (5cm) Rod

- MOTOR : TEFC 208, 230, 460 Volt, 60 Hertz, 3 Phase

- ENCLOSURE : NEMA 12 Rated, UL Approved

- CONTROLS : UL/CUL/CE Approved, NEMA 12 Rated

- HYD SYSTEM PRESSURE : 4,000 PSI (276 Bar)

- OVERALL PLATEN FORCE : 159,400 lbs. (72 tonne)

- PLATEN PSI : 92 PSI (6.33 BAR)

- CYCLE TIME : 29 sec. – 21 sec. Short Stroke

- TARGET BALE SIZE : 60”L (152cm) x 48”W (122cm) x 30”H (76cm)

Bale Weights *

- OCC : 1,200 lbs. (544kg) TPH 3.3

- MAGAZINES : 2,000 lbs. (907kg) TPH 7.5

- NEWSPAPER : 1,500 lbs. (680kg) TPH 6.4

- OFFICE PAPER : 1,600 lbs. (726kg) TPH 6.8

- HDPE : 1,100 lbs. (499kg) TPH 2.3

- PET : 800 lbs. (363kg) TPH 1.5 (May vary with percent of capped bottles)

- ALUMINUM CANS : 625 lbs. (284kg) TPH 2.3

- TIN CANS : 1,200 lbs. (544kg) TPH 4.5

Applications

2R10 Two Ram Balers bale the following materials:

- Office Paper

- Newspaper

- OCC

- Magazines

- PET

- HDPE

- Aluminum Cans

- Tin Cans

- Plastic Film

- Carpet Padding

- Textiles

- Other materials

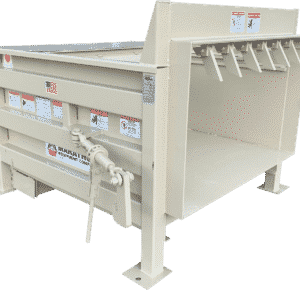

Features

- The 2R63 baler is manufactured standard with either left-hand or right-hand eject

- U.S. Wire Tie Systems Automatic 13 Gauge Wire Tier, Model 343

- 20 HP TEFC Motor, Standard Voltage – 208, 230, 460 Volt, 60 Hertz, 3 Phase

- 29 Second Main Ram Dry Cycle Time

- Short Stroke Selector Reduces Cycle Time to 21 Seconds

- Excel’s 1-2-3 Warranty (1 year Labor, 2 Years Parts, 3 years Structural & Cylinder) (USA Only)

- Remote Operating Control Located on Pedestal

- Percent of Bale Complete Indicator Lights

- Automatic Bale Sizing System

- Full Platen Penetration

- Complete with MV32 Hydraulic Oil

- NEMA 12 rated Enclosures and Controls

- Power Unit Mounted on back of the Machine for Space Savings

- Air/Oil Heat Exchanger

- One Spool of 13 Gauge Ultra High Tensile Galvanized Wire

- Paint – Excel Blue

- Standard Hopper

- Lower Photo Eye

- UL, CUL, CE Approved

- Available with an Excel above ground or in-ground conveyer for a turn-key system

Specifications

Structural

- HEIGHT : 62” (158cm) Loading 52.5” (135cm) Frame

- LENGTH : 16’ 2” (493cm)

- WIDTH : 16’ 11” (516cm)

- CHAMBER : 60” (153cm)W x 29.5” (75cm)H

- FEED OPENING : 54” (138cm)W x 40” (102cm)L

- BALER SHIPPING WEIGHT : 32,730 lbs. (14,846kg) (as shown)

Performance Data

- PUMP : 2 – 6” (15cm) Bore x 74” (188cm) Stroke x 4” (10cm) Hard Chrome Rod

- DIRECTIONAL VALVE : Hi-Flow Cushion Shift Design

- CYLINDERS : 105 gal. (399 liters)

- OIL RESERVOIR : 105 gal. (399 liters)

- DOOR LATCH CYL. : 434 Gal. (130 liters) Pressure Compensated Horse Power Limited Piston Pump

- MOTOR : 20 HP TEFC 230-460 V 3 PHASE

- ENCLOSURE : NEMA 12 RATED

- CONTROLS : UL/CSA/CE Approved NEMA 12 Rated

- HYD SYSTEM PRESSURE : 95 PSI

- OVERALL PLATEN FORCE : 29 Seconds – 21 Sec. Short Stroke

- PLATEN PSI : 60”L x 48”W x 30”H (152cm L x 122cm W x 76cm H)

- CYCLE TIME : Hi-Flow Cushion Shift Design

- TARGET BALE SIZE : 60”L x 48”W x 30”H (152cm L x 122cm W x 76cm H)

Bale Weights *

- OCC : 1,200 lbs. (544kg) TPH 3.3

- MAGAZINES : 2,000 lbs. (907kg) TPH 7.5

- NEWSPAPER : 1,500 lbs. (680kg) TPH 6.4

- OFFICE PAPER : 1,600 lbs. (726kg) TPH 6.8

- HDPE : 1,100 lbs. (499kg) TPH 2.3

- PET : 800 lbs. (363kg) TPH 1.5 (May vary with percent of capped bottles)

- ALUMINUM CANS : 625 lbs. (284kg) TPH 2.3

- TIN CANS : 1,200 lbs. (544kg) TPH 4.5

Applications

2R10 Two Ram Balers bale the following materials:

- Office Paper

- Newspaper

- OCC

- Magazines

- PET

- HDPE

- Aluminum Cans

- Tin Cans

- Plastic Film

- Carpet Padding

- Textiles

- Other materials

Please contact one of the EMP Partner(s) below: