Aggressive Hydraulics Custom Telescopic Hydraulic Cylinders

Telescopic hydraulic cylinders utilize multiple nested stages, achieving a long working stroke in compact/retracted form. Aggressive Hydraulics designs and engineers application-specific telescopic cylinders, purpose-built to withstand your application demands. Our experienced engineering team helps you work through design considerations to ensure your cylinder meets your requirements.

Common Types of Telescopic Cylinders

- Single-acting telescopic cylinders

- Double-acting telescopic cylinders

- Combination of single- and double-acting telescopic cylinders

Telescopic Cylinder Applications

Common mobile hydraulic applications for telescopic cylinders include:

- Garbage trucks

- Dump trucks

- Agricultural equipment

- Construction equipment

- Transfer trailers

- Single and Double Acting Telescopic Hydraulic Cylinder Types

- Common hydraulic pressures up to 2,000 psi, special applications optional up to 3,000 psi

- Max bore size available up to 15″

- Min stage size available down to 3/4″

- Common stroke lengths up to 500″

- Number of stages common up to 5

- Single-acting cylinders use hydraulic pressure to extend, and retract due to load from gravity or some other external force.

- Hydraulic flow and pressure extends the cylinder

- Gravity or some other external force will retract the cylinder

- Holds position

- Long stroke in a compact closed length

- Larger outer diameter than rod cylinders

- Less complex design than double acting

- Double-acting cylinders use hydraulic force for both extension and retraction.

- Hydraulic power retracts cylinder as opposed to gravity/force

- Retract force is able to pull load

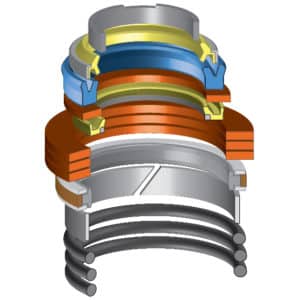

- Conventional telescopic cylinders

- Both ports located on rod end

- Piston seals are typically cast iron rings

- Cylinder is not designed to hold load in exact positions (drifting)

- Minimum flow required to prevent stalling

- Special features can be designed into telescopic cylinders

- Both ports on the barrel design avoids moving hoses and wear patterns

- Positive piston seals allow cylinder to hold the load and eliminate the minimum flow requirement

- Less dead lengths per stage than a conventional double acting telescopic

Partially double-acting cylinders are typically used in over-center applications. These cylinders will provide retract force for a portion of the stroke, and gravity completes the retract cycle.

- Plunger rod can be double acting and sleeves single-acting.

- Largest sleeve can be double acting and balance of sleeves and plunger rod single-acting.

- Skip-a-sleeve option, which is a sleeve or stage is skipped during design, thus increasing effective area and retract force.

We can handle all of your mounting requirements. Contact us for any special mounting requests.

- Clevis

- Clevis – Threaded

- Cross Tube

- Drill Thru Base Mount

- Drill Thru Rod End

- Flange

- Foot (Heavy-Duty)

- Foot (Light-Duty)

- Lug

- Spherical Base End

- Spherical Rod End

- Threaded Base End (Female)

- Threaded Base End (Male)

- Threaded Rod End (Female)

- Threaded Rod End (Male)

- Trunnion